The A Class Tram stands as one of the most distinctive and historically significant tram types on the Melbourne tram network.

Built by Commonwealth Engineering (Comeng) at Dandenong between 1984 and 1987, the A class was a direct evolution of the Z-class trams yet reflected a significant political and engineering shift in Victoria’s public transport design philosophy.

Seventy units were built in total, 28 A1-class trams and 42 A2-class trams marking Comeng’s final single-body tram production before Melbourne transitioned to articulated configurations with the B-class.

For rolling stock engineers, the A class represents a key bridge between mechanical standardisation and passenger-centred design, a transition that would influence decades of tram procurement policy.

Origins of the A Class Tram

In 1982, a change in government reshaped Victoria’s transport manufacturing agenda.

The incoming Cain Labour Government, under Minister for Transport Steve Crabb, sought to modernise Melbourne’s tram fleet and redefine its visual identity.

Comeng had already prepared drawings for what would have been the Z4 class, a continuation of the Z3 series. However, Minister Crabb insisted on a tram that would distinguish itself from its predecessors, a design with a wider, flatter front rather than the sharply pointed aesthetic of the Z-class.

His vision extended beyond aesthetics; he wanted improved passenger accessibility and quicker loading times, leading to the introduction of two large doors between the bogies.

Thus, the Z4 project evolved into the A Class Tram, a decision that blended political will, industrial capability, and urban transport reform.

The result was a tram that looked and operated differently, even though beneath its body shell it remained mechanically similar to the Z3.

Manufacturing and Production of the A Class Tram

Comeng’s Dandenong factory was at the centre of Melbourne’s rolling stock innovation during the 1980s.

The company had already built multiple tram series for the Melbourne & Metropolitan Tramways Board (MMTB), and the A class became one of its last major projects before the shift toward articulated trams and corporate restructuring in the late decade.

- A1 Class: 28 units built between 1983 and 1985 (fleet numbers 231–258).

- A2 Class: 42 units built between 1985 and 1987 (fleet numbers 259–300).

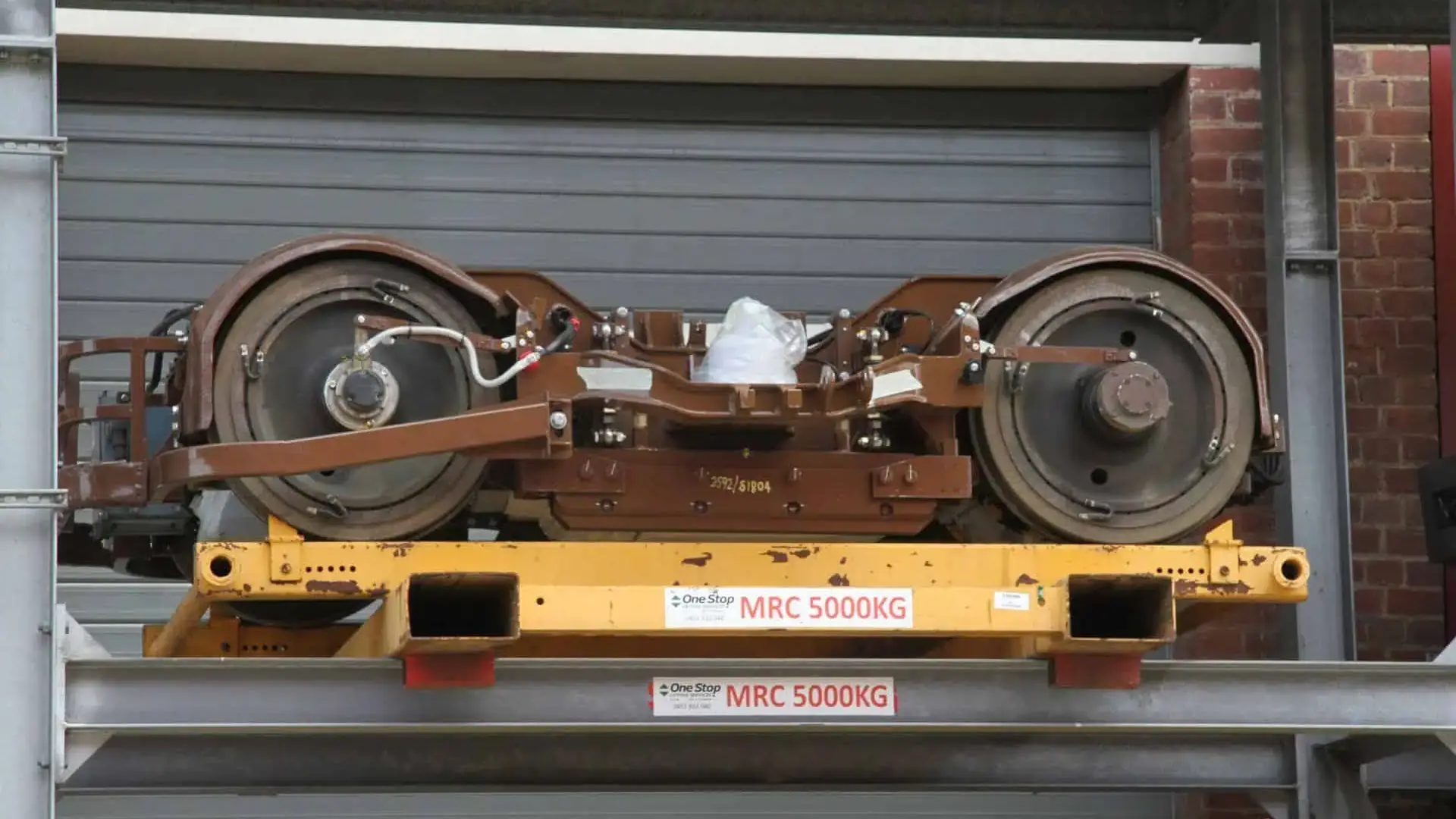

Each tram was assembled using welded steel construction with modular electrical equipment sourced from AEG (Germany), including chopper controls, traction motors, and Düwag-pattern bogies.

The trams were compact, robust, and designed for Melbourne’s existing infrastructure, making them suitable for routes with lower passenger demand or tighter curves.

A Class Tram Technical Specifications

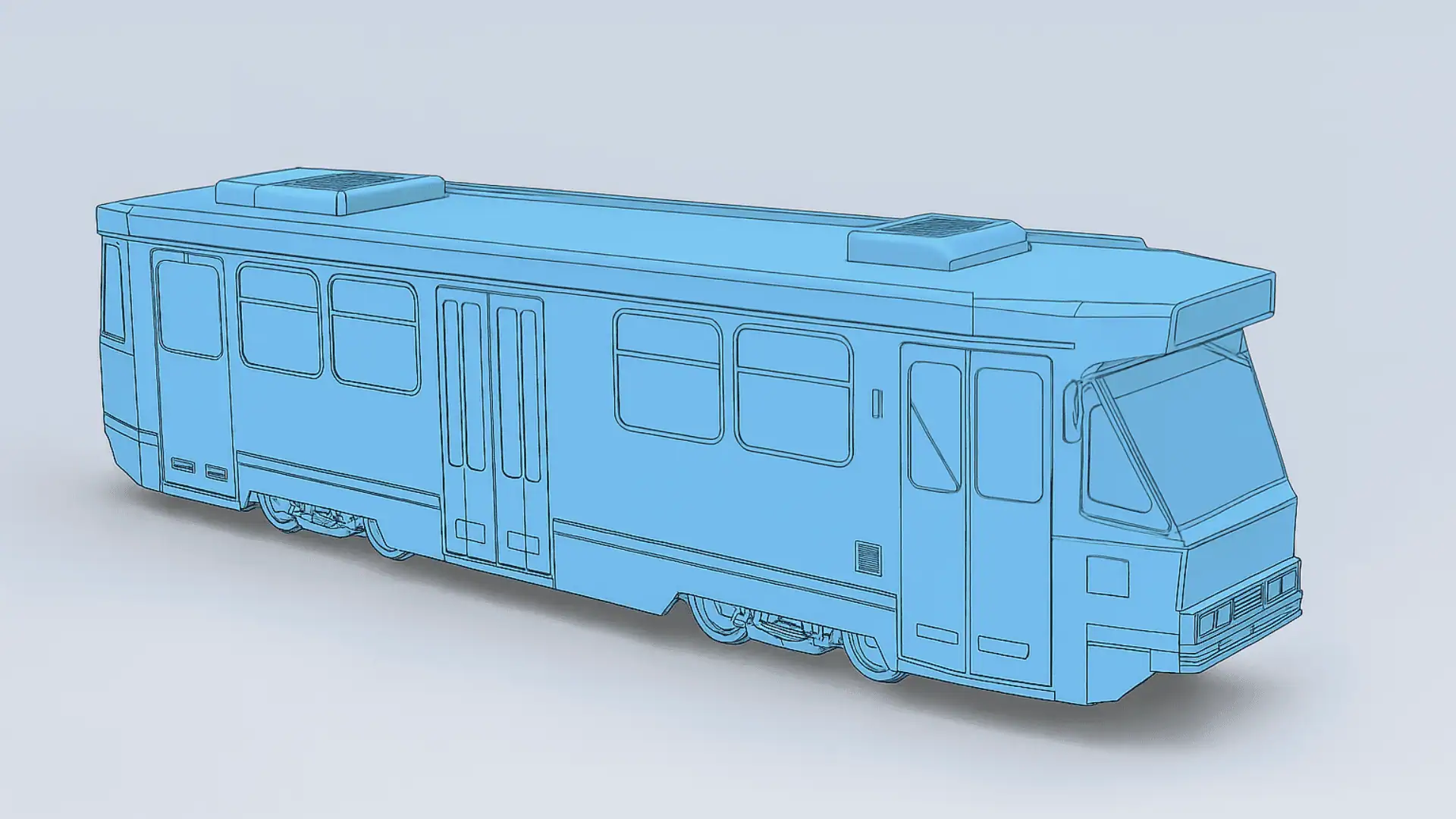

The A Class tram is a three-door bogie saloon design, structurally compact yet powerful enough for intensive urban operation.

| Specification | A1-Class |

| Builder | Commonwealth Engineering (Comeng), Dandenong |

| Built | 1984–1985 |

| Units Built | 28 |

| Seating Capacity | 42 |

| Weight (Tare) | 22.2 tonnes |

| Length | 15.01 m |

| Width | 2.67 m |

| Height | 3.34 m |

| Wheel Arrangement | Bo-Bo |

| Wheelbase | 1800 mm |

| Bogie Centres | 8500 mm |

| Wheel Diameter | 660 mm |

| Bogies | Düwag tandem drive |

| Controller | Siemens/AEG chopper control |

| Traction Motors | 2 × AEG ABS 332, 195 kW each |

From an engineering standpoint, these specifications positioned the A class tram as a refined variant of the Z3.

The same electrical traction systems were retained for parts commonality and simplified maintenance, but improvements were made in door mechanisms, driver ergonomics, and passenger flow management.

A Class Tram Engineering Innovations and Challenges

While the A class reused proven Z3 mechanical systems, engineers faced a notable challenge.

Fitting all underframe electrical and pneumatic equipment into a shorter chassis. The revised door arrangement, two large step-wells instead of one, reduced the available equipment space beneath the floor.

To overcome this, Comeng’s engineers restructured the component layout, ensuring the tram remained balanced and maintainable. The electrical gear, air compressors, and control systems were redistributed, demonstrating how incremental innovation could be achieved without redesigning an entire platform.

From an electrical engineering perspective, the AEG chopper controller represented a milestone. It replaced the older resistance control method, providing smoother acceleration, energy savings, and less mechanical wear on contactors and resistors.

The result was a tram that performed efficiently across Melbourne’s stop-and-go routes while reducing maintenance intervals.

A1 Class Tram Design and Early Service

The A1-class trams, introduced from 1983 to 1985, embodied the Cain Government’s policy to modernise public transport visually and operationally.

They were the first trams to adopt a more streamlined, less angular front, giving them a contemporary appearance compared to the utilitarian Z-series.

Key Features

- Improved ventilation and airflow through redesigned roof vents.

- Dual central passenger doors, reducing boarding times at peak hours.

- AEG-controlled chopper system identical to the Z3, ensuring reliability and parts interchangeability.

- Trolley pole power collection, later upgraded to pantographs between 1987 and the late 1990s.

The first A1 tram was delivered on 12 December 1983 and began passenger service on 13 June 1984. These trams quickly became a mainstay on Kew Depot routes, particularly Route 42 (Mont Albert – City) and Route 48 (North Balwyn – Spencer Street).

A notable engineering variant was tram A1.231, which gained attention when it was painted in chocolate and cream livery in 1995 to celebrate the 75th anniversary of Kew Depot. Although this tram was later destroyed by fire in 2013, it remains one of the most memorable vehicles in Melbourne’s tram heritage.

A2 Class Tram Refinement and Reliability

The A2-class trams, built between 1985 and 1987, marked the final evolution of the A platform. While visually almost identical to the A1, the A2 included significant mechanical refinements:

- Introduction of Hanning & Kahl braking systems, offering more consistent braking performance.

- A redesigned door-operating mechanism to reduce failures.

- Delivered pantograph-only from new, eliminating the need for trolley poles.

These trams were the first Melbourne trams built without provision for conductor consoles, reflecting the network’s shift toward driver-only operation and automated ticketing systems in the following decade.

Many A2s carried Bicentennial branding due to funding assistance from the Commonwealth Government’s 1988 program, highlighting the political cooperation behind Melbourne’s transport renewal.

Tram A2.296 received special modification with high-beam headlights, similar to those fitted to the B2-class, allowing engineers to trial illumination standards for light-rail routes. It was the only non-articulated tram to receive this upgrade.

Operational Deployment

Initially, both A1 and A2 trams were concentrated at Kew Depot, but operational needs saw later redeployments. With the opening of the St Kilda and Port Melbourne light-rail lines in 1987, several A2s were allocated to South Melbourne and North Fitzroy depots.

By the late 1980s, the arrival of the B2-class articulated trams allowed A2s to return to Kew. Throughout the 1990s, they operated predominantly on eastern corridor routes including:

- Route 42 (Mont Albert – City)

- Route 48 (North Balwyn – City/Spencer Street)

- Peak-hour short-workings along Collins and LaTrobe Streets

For the Chapel Street lines (78 and 79), only pole-equipped A1s could operate until pantograph conversion of the overhead wiring occurred in the late 1990s. The last six A1s (Nos. 231–236) retained trolley poles for nearly two decades, becoming icons of a fading electrical era.

A Class Tram Network Integration and Modernisation

When Melbourne’s tram network was privatised in August 1999, all A-class trams transferred to Yarra Trams. The operator undertook multiple upgrades:

- 2005–2007: Replacement of rollsigns with LED destination systems.

- 2007: Installation of air conditioning in driver cabins to improve occupational comfort.

- 2017: Integration of automated passenger information systems, aligning them with modern fleet standards.

From an engineering management viewpoint, these retrofits exemplify the adaptability of the A-class frame and electrical systems. Despite being mid-1980s technology, their robust construction allowed new components to be integrated without compromising performance or safety.

Mechanical Relationship Between The Z vs A Class Tram

Understanding the relationship between the Z and A classes is crucial for any rolling stock engineer examining Melbourne’s design lineage.

Key Differences

- Body Design: The A class adopted a flat, wider front instead of the Z-class’s pointed nose.

- Doors: Two large double doors between bogies, improving passenger movement.

- Ventilation: Enhanced ventilation compared with earlier Z models.

- Braking: The A2’s Hanning & Kahl brakes provided better modulation.

- Electrical Systems: Both used Siemens/AEG chopper control and AEG motors.

- Aesthetic and Ergonomics: The A class marked the first significant design consideration for driver comfort and urban image.

Mechanically, however, the Z3 and A1/A2 trams share nearly identical bogies, motors, and controllers. For maintenance and spare-part management, this interchangeability proved cost-effective for the MMTB and later Yarra Trams.

The major evolution lay in passenger experience and external design rather than propulsion technology. Engineers thus classify the A class as an incremental development, not a technological revolution.

World’s Largest Tram Refurbishment Project (RSAW)

Starting in 2018, the government launched the program to refurbish over 85% of the tram fleet. The scope includes life extensions, deep overhauls, deep cleans, interior, exterior upgrades and system modernisation.

By 2022, the program had already refurbished 300 trams, with over 150 jobs supported in the supply chain and is widely referred to as the largest tram life-extension and refurbishment program in the world.

Copamate’s Involvement

Copamate was selected as a major fabrication and refurbishment partner. Their work includes manufacturing new windows, refurbishing and manufacturing tram doors, tram fibreglass step wells, tram fibreglass seat surrounds, and various tram sheet metal panels.

Their precision engineering ensures older trams, including A Class trams, can meet modern safety, comfort and accessibility standards while preserving design geometry.

A Class Tram Legacy and Current Status

Nearly four decades after entering service, the A class trams remain operational across Melbourne’s network. Their longevity is a testament to Comeng’s engineering quality and the strategic foresight of designing a fleet that could be modernised incrementally.

As of 2020, 69 of the 70 A-class trams remained in service, an exceptional survival rate. Their continued use demonstrates that even with modest capacity, well-engineered rolling stock can serve efficiently for over forty years when maintained and upgraded systematically.

The A class today represents a crucial engineering case study in lifecycle management and retrofit planning. Rolling stock engineers continue to examine its structure for lessons in fatigue resistance, electrical redundancy, and driver ergonomics.

The A class tram shows thoughtful standardisation, incremental upgrades and manufacturer collaboration can produce enduring public assets that return value across multiple decades.

Comparative A Class Tram Summary

| Aspect | Z1/Z2 | Z3 | A1/A2 (A Class) |

| Production Years | 1975–1979 | 1979–1983 | 1983–1987 |

| Body Design | Pointed, angular | Refined, still narrow | Flatter, wider nose |

| Doors | Single centre | Single centre | Two large double doors |

| Power Control | Camshaft | Siemens/AEG chopper | Siemens/AEG chopper |

| Bogies | Early MMTB design | Düwag tandem drive | Düwag tandem drive |

| Brakes | Conventional | Improved | Hanning & Kahl (A2) |

| Power Collection | Trolley pole | Trolley pole | Trolley pole → Pantograph |

| Driver Comfort | Minimal | Moderate | Enhanced cab environment |

| Passenger Flow | Constrained | Better than Z1/Z2 | Much improved |

| Visual Identity | Sharp | Transitional | Modernised, flat front |

Final Notes

The A Class Tram is more than a continuation of Melbourne’s Z-class; it is a symbol of political vision meeting mechanical pragmatism. Conceived in the early 1980s amid shifts in government policy, it reflected Victoria’s ambition to present a modern, efficient, and passenger-friendly tram network.

For engineers, it remains a textbook example of evolutionary design, combining proven mechanics with practical human-centred modifications. For policymakers, it stands as evidence that infrastructure progress does not always demand revolutionary change, sometimes the greatest advancements come from refining what already works.

Today, the A class continues to serve the people of Melbourne faithfully, a rolling testament to Comeng’s craftsmanship and the foresight of those who demanded better transport for the city. Its engineering integrity ensures that even as new low-floor trams replace older stock, the A Class Tram will remain one of Melbourne’s most respected and enduring machines in urban transport history.

Read more about rail projects such as the Future Fleet Program in NSW.

Get insights on industry news and posts.

Related Posts

July 24, 2025

Tooling, Fixtures & Jigs Overview | Rail Applications

Tooling, jigs & fixtures is the physical interface between the design and the…

July 3, 2025

Melbourne Metro Tunnel Project | 2025 Update

Melbourne’s Metro Tunnel Project, set to open 2025 is the largest rail…

May 27, 2025

Future Fleet Program Overview | Top 5 Benefits

With the announcement of the Future Fleet Program, New South Wales has…