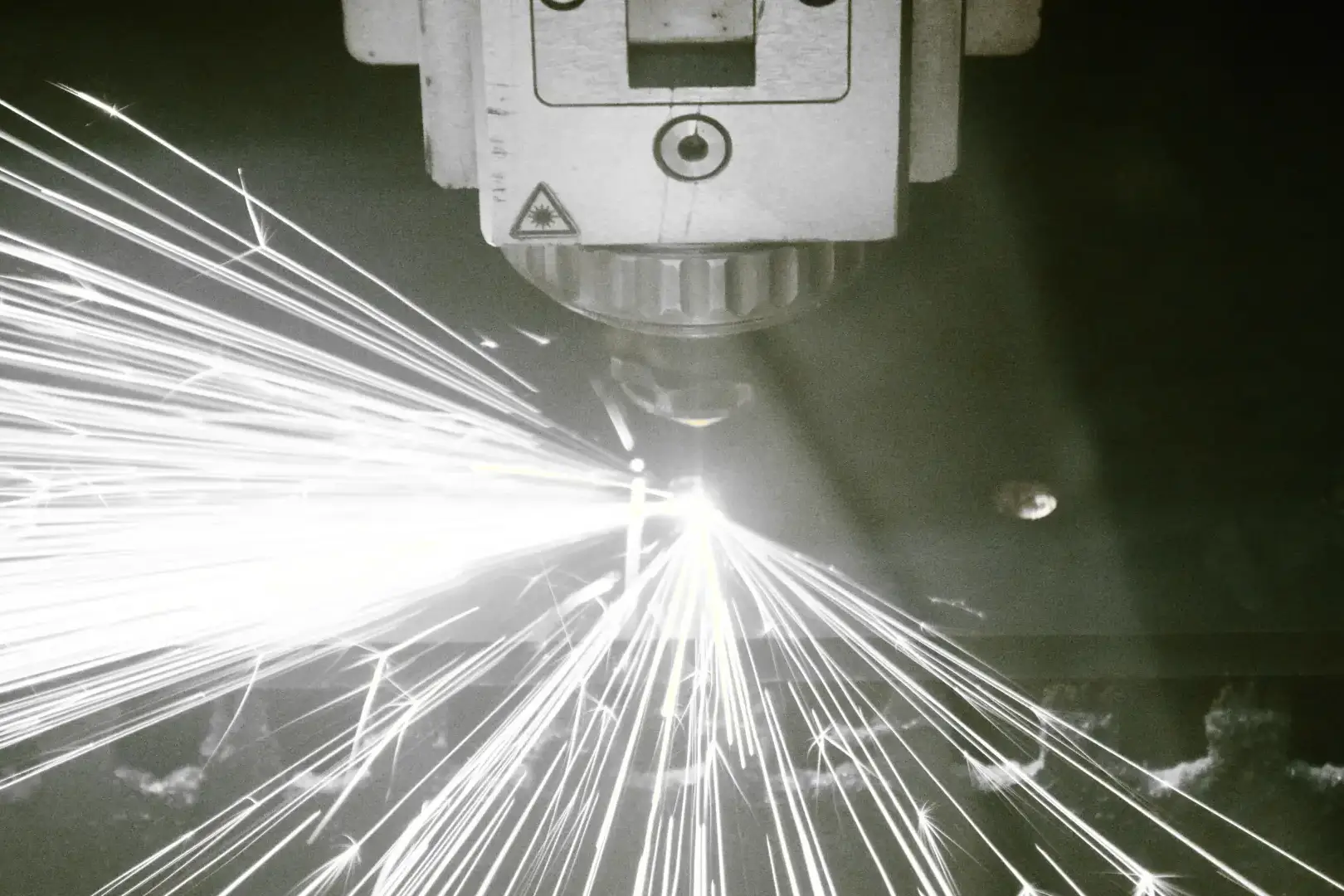

When precision, speed and material quality are critical, laser cutting is the manufacturing process that delivers consistent results across a wide range of applications. From rail and defence to infrastructure, automotive and pipeline sectors, laser cutting remains one of the most reliable methods for achieving intricate profiles and high tolerance cuts.

At Copamate, we specialise in precision laser cutting across a diverse range of laser cutting materials, offering industry-grade capabilities backed by engineering expertise and manufacturing excellence. This guide outlines the materials we work with, their characteristics and the maximum thicknesses we can process to meet your project needs.

Aluminium Laser Cutting (Up to 10mm)

Aluminium is a highly versatile material commonly used across sectors that demand lightweight, corrosion-resistant and strong components. Due to its high thermal conductivity and reflectivity, aluminium requires specialised handling and high-powered laser settings to ensure clean, burr-free cuts.

At Copamate, we cut aluminium sheets up to 10mm thick using advanced fibre laser systems that ensure minimal heat-affected zones and excellent edge quality.

Applications: Automotive heat shields, aerospace brackets, control panels, housing enclosures and electrical components.

Advantages:

- High strength-to-weight ratio

- Excellent corrosion resistance

- Smooth finish for anodising or coating

Industries: Automotive, Rail, Defence, Electronics, Aerospace

Steel Laser Cutting Materials (Sheet Steel)

Laser cutting steel sheet remains one of the most requested services in industrial manufacturing due to steel’s affordability, strength and ease of fabrication. Copamate handles both mild steel and stainless steel, each offering unique benefits for specific applications.

Mild Steel Laser Cutting (Up to 12mm)

Mild steel, also known as carbon steel, is highly machinable and cost-effective, making it ideal for structural components, enclosures and heavy-duty brackets.

Our fibre laser machines can cut mild steel up to 12mm thick with fast turnaround times and repeatable accuracy.

Applications: Base plates, brackets, frames, equipment mounts

Advantages:

- Affordable and readily available

- Easy to weld and machine

- Strong and formable

Industries: Infrastructure, Mining, Automotive, Rail

Stainless Steel Laser Cutting (Up to 10mm)

Stainless steel is valued for its superior corrosion resistance and high-temperature tolerance. It is often used in critical environments where hygiene or exposure to moisture is a concern.

Laser cutting stainless steel requires tighter control due to reflectivity and alloy composition. Our systems are calibrated for cutting stainless up to 10mm with smooth, dross-free edges.

Applications: Exhaust systems, food processing components, railcar interiors, pump housings

Advantages:

- Corrosion-resistant

- Aesthetic finish with optional polishing

- Heat-resistant and hygienic

Industries: Rail, Defence, Food Manufacturing, Infrastructure

Brass Laser Cutting (Up to 8mm)

Brass offers excellent machinability, thermal conductivity and aesthetic appeal, often chosen for components requiring both function and finish.

Due to its reflectivity, precision laser systems are essential. We process brass sheets up to 8mm thick with minimal oxidation and post-processing needs.

Applications: Valve plates, decorative panels, electronic fittings

Advantages:

- Attractive golden finish

- Corrosion-resistant

- Good conductor of heat and electricity

Industries: Rail, Plumbing, Electrical, Architectural

Copper Laser Cutting (Up to 8mm)

Copper’s high electrical and thermal conductivity make it indispensable for energy transfer and electrical components. Laser cutting copper is technically complex due to its high reflectivity and conductivity.

Copamate uses advanced laser optics to safely and efficiently cut copper sheets up to 8mm thick.

Applications: Busbars, grounding strips, heat sinks, contact terminals

Advantages:

- Exceptional conductivity

- Corrosion-resistant

- Anti-microbial properties

Industries: Power Distribution, Rail Signalling, Defence Electronics

Manganese Laser Cutting (Up to 7mm)

Manganese steel is known for its extreme impact resistance and high abrasion tolerance, making it essential for wear-resistant components in heavy industries.

Laser cutting manganese requires precision and speed to minimise thermal distortion. We handle manganese sheets up to 7mm thick.

Applications: Crusher liners, rail crossings, bucket wear plates

Advantages:

- Impact and abrasion resistant

- Work-hardening properties

- Long service life in high-wear environments

Industries: Rail, Mining, Defence

Galvanised Steel Laser Cutting (Up to 10mm)

Galvanised steel includes a protective zinc coating to prevent rusting. It is widely used in outdoor, moisture-prone or corrosive environments.

Laser cutting galvanised steel requires clean extraction to avoid zinc vapour buildup. Copamate cuts galvanised sheets up to 10mm with controlled ventilation systems for safe and efficient operation.

Applications: Ducting, fencing components, vehicle bodies, trays

Advantages:

- Corrosion-resistant

- Cost-effective

- Easy to fabricate and weld

Industries: Infrastructure, Rail, Automotive, HVAC

Zincalume Laser Cutting (Up to 10mm)

Zincalume combines zinc, aluminium and silicon for long-lasting surface protection and structural integrity. It’s ideal for architectural and industrial applications requiring enhanced corrosion resistance and longevity.

We offer laser cutting for Zincalume sheet up to 10mm thick with smooth, reflective edges ideal for coatings or post-processing.

Applications: Roofing, flashing, brackets, outdoor enclosures

Advantages:

- Long lifespan

- Excellent corrosion resistance

- Low maintenance material

Industries: Construction, Infrastructure, Rail

Why Copamate for Laser Cutting?

Copamate offers engineering-grade laser cutting services, tailored for high-performance industries that demand precision, compliance and material traceability.

Our in-house manufacturing capabilities, coupled with a team of technical specialists, allow us to deliver complex cutting jobs at scale, on time and with industry-specific requirements in mind.

Key Benefits:

- Cutting capability up to 12mm on multiple materials (soon to be upgraded)

- Laser cutting technology for improved efficiency and sustainability

- Australian-based support with ISO 9001, IRIS and AS9100 compliant manufacturing

- Expertise in interpreting CAD and engineering drawings

- Short lead times and fast quoting

Our clients in rail, defence, automotive, and infrastructure rely on us for essential components that meet the highest quality and durability standards.

Final Notes

Understanding the properties, benefits and limitations of various materials is key to achieving precision and performance in laser cutting applications. Whether you are working on a rail infrastructure upgrade, fabricating components for defence, or developing enclosures for automotive systems, choosing the right material and supplier can determine both the durability and cost-effectiveness of your project.

Copamate brings technical proficiency, quality assurance and customer-focused service to every laser cutting task. With the ability to process an extensive range of materials up to 12mm thick, we are equipped to handle the demands of Australia’s leading industries. Our strength lies in blending manufacturing capabilities with engineering insight, helping customers achieve consistent results across every application.

When material choice matters and precision cannot be compromised, Copamate is the partner manufacturers trust.

Get insights on industry news and posts.

Related Posts

December 5, 2025

Jo Hocking | Woman Manufacturer of the Year 2025

On 9 October 2025 Jo Hocking, Director of Finance, Sales and Marketing at…

October 29, 2025

A Class Tram | Details & History

Learn how the A Class Tram evolved from Z3, with A1 and A2 changes, braking,…

September 17, 2024

Laser Cutting | Professional Overview

Laser cutting is a precise, computer-controlled manufacturing process that…