Today’s rail transportation is known for efficiency and safety, trains heavily rely on the design and functionality of their key components. One of the most critical elements is the train bogie. Acting as the foundation for the train’s wheelsets, bogies are integral to the smooth operation of rail vehicles. Whether you’re an engineer, a rail enthusiast, or simply curious about how trains stay on track, this guide will provide valuable insights into the role of bogies in rail transport.

What are Train Bogies?

Train bogies, also known as railway bogies, are the undercarriage assemblies that support the weight of a train and ensure its proper functioning during travel. A bogie consists of a frame that houses two or more wheelsets, which are connected through a suspension system that allows movement, particularly in curves. Bogies are essential for reducing the forces on the track, improving the train’s stability, and enabling a smooth ride for passengers or freight.

The development of rolling stock bogies significantly advanced railway technology, replacing the fixed axle design that was initially used in early railway vehicles. By allowing the wheelsets to pivot within the bogie frame, the vehicle’s ability to navigate curves and uneven tracks improved significantly, providing greater comfort and safety.

What is the Purpose of Train Bogies?

The primary purpose of a train bogie is to support and stabilise the vehicle while ensuring it remains connected to the tracks. Here are the key purposes:

- Support the Vehicle’s Weight: Bogies distribute the weight of the train evenly across the wheelsets, helping maintain the structural integrity of both the train and the track.

- Enhance Stability: The bogie’s suspension system helps absorb the vertical and lateral forces during travel, minimising the impact on the train’s frame and reducing track wear.

- Ensure Proper Guidance: The bogie allows for better guidance along curves, enabling trains to travel on tracks with smaller radii without the risk of derailment.

- Reduce Wear on Track: The bogie’s design reduces the stress placed on the track, contributing to longer-lasting infrastructure and more efficient operations.

- Vibration Isolation: The bogie’s suspension isolates vibrations from the track, ensuring a smooth ride, particularly for passenger trains.

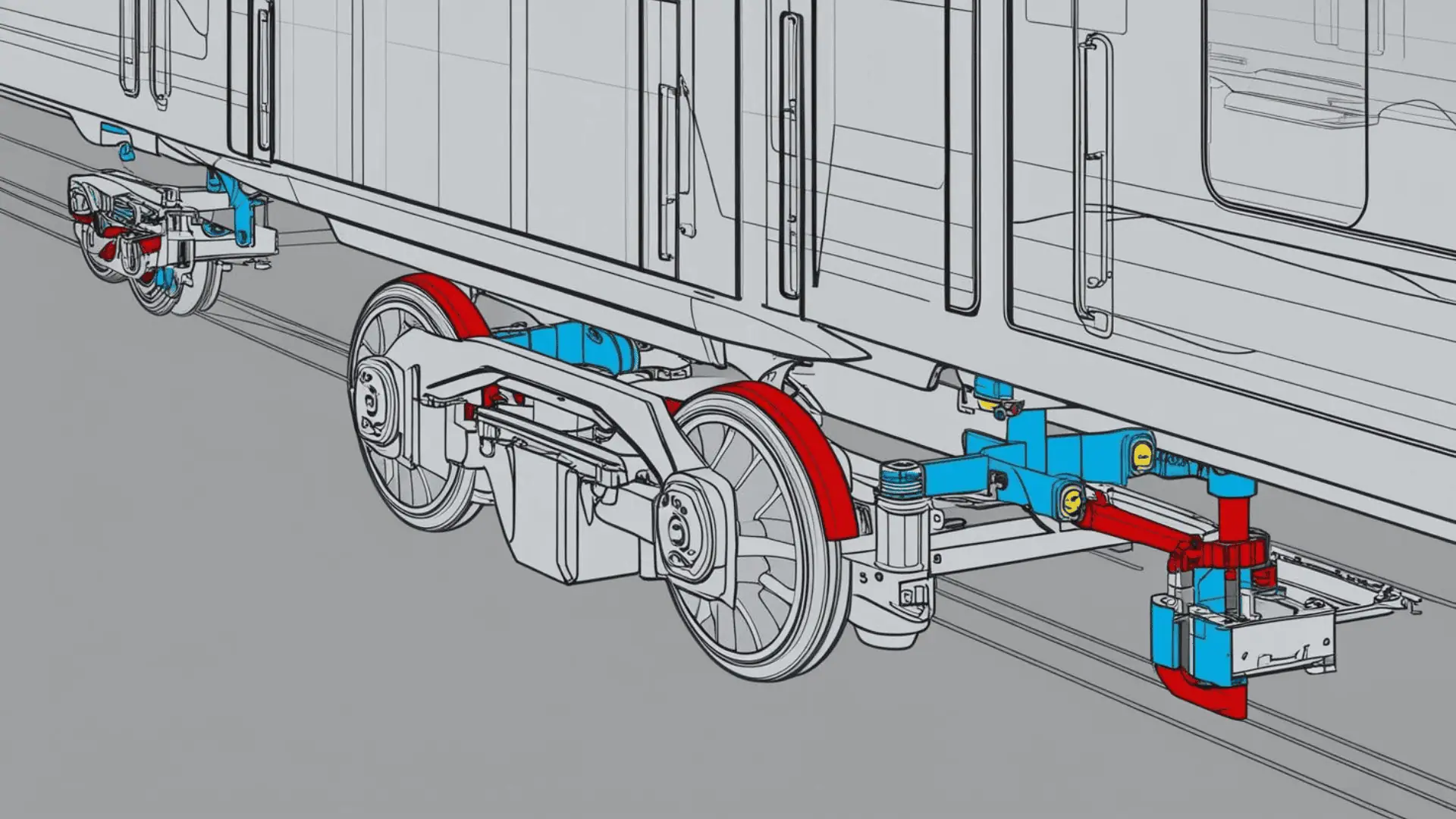

What are The Main Components of a Bogie?

- Frame: The central structure of the bogie, which supports the wheelsets and connects them to the train. It can be either an external or internal frame, depending on the design requirements.

- Wheelsets: These are the wheels mounted on axles that rotate with the movement of the train. Wheelsets are typically mounted within the bogie frame and can turn independently to navigate curves.

- Suspension System: Consists of springs or air suspensions that absorb vertical and horizontal forces. This system isolates the vehicle from shocks and vibrations from the track.

- Axle Bearings: These allow for smooth rotation of the wheelsets and reduce friction between the wheelset and the bogie frame.

- Braking System: Typically, disc or drum brakes are attached to the wheelsets, ensuring the train can slow down or stop effectively.

- Pivot Point: A critical component that allows the bogie to rotate relative to the vehicle frame, improving the ability to navigate curves.

- Bolsters: Cross beams within the bogie that allow for additional flexibility and load-bearing capability.

What are Modern Train Bogies Like?

Modern train bogies have evolved significantly in design and materials, reflecting advancements in technology and the need for higher speeds, greater comfort, and reduced operational costs. Features of modern bogies include:

- Advanced Materials: Modern bogies are often made from lightweight yet strong materials such as high-strength steel, aluminum alloys, and composite materials to reduce weight without compromising durability.

- Improved Suspension: Air suspensions or hydraulic systems provide superior comfort and stability, especially for high-speed trains, by reducing vibrations and impacts from track irregularities.

- Lower Maintenance Needs: Improved design and materials lead to fewer mechanical failures and less frequent maintenance, resulting in better overall operational efficiency.

- Noise Reduction: Innovations in design, such as the use of sound-insulating materials, have made modern bogies quieter, enhancing passenger comfort, particularly in urban transit and high-speed trains.

- Modular Design: Many modern bogies are designed to be easily disassembled for maintenance, allowing quick repair or replacement of individual components.

How are Train Bogies Made?

Design and Engineering: Before the manufacturing process engineers design bogies based on engineering and design factors like:

- Load-bearing capacity

- Speed requirements

- Track gauge compatibility

- Suspension and damping needs

- Safety and regulatory compliance

Material Selection: Bogies are made out of high-strength steel, cast steel or aluminium alloys to balance strength and weight. The materials used include:

- Mild steel or high-strength steel: Common for heavy-duty freight and passenger bogies

- Cast steel: Used in some bogie frames for increased durability

- Aluminum alloys: Used for high-speed and lightweight applications

Manufacturing Process

Step 1: Frame Fabrication

The bogie frame, also called the bogie bolster, is the main structural component that holds the wheelsets and supports the train body. It is typically made from welded steel plates or cast steel.

- Cutting & Shaping: Laser cutting, CNC machining, or plasma cutting are used to shape steel plates.

- Welding: High-precision robotic welding is used to join steel parts together.

- Heat Treatment: Frames undergo heat treatment to relieve stress and improve strength.

- Machining & Drilling: CNC machines are used for precision drilling and finishing.

Step 2: Wheelset Manufacturing

Each bogie has two wheelsets, which include wheels and an axle.

- Forging: Wheels are forged from solid steel billets.

- Heat Treatment & Hardening: To increase wear resistance, wheels undergo heat treatment and are hardened at the tread area.

- Axle Machining: Axles are turned on CNC lathes and ground to precise tolerances.

- Press-Fitting: Wheels are pressed onto the axle using hydraulic presses.

Step 3: Suspension System Production

Train bogies use primary and secondary suspension systems. Components include:

- Helical or rubber springs (absorbing shocks from the track)

- Dampers and hydraulic cylinders (controlling motion and vibration)

- Anti-roll bars (enhancing stability)

- These parts are manufactured through casting, forging, and machining before being assembled into the bogie.

Step 4: Braking System Integration

Brakes are integrated into the bogie for train stopping power. Components include:

- Disc brakes or tread brakes

- Air brake cylinders

- Brake pads and calipers

- These parts are sourced from suppliers and installed on the bogie.

Step 5: Final Assembly

Once all components are manufactured, they are assembled in the following sequence:

- Wheelsets are installed into the bogie frame.

- Suspension components are mounted.

- Braking systems are integrated.

- Bearings and lubrication systems are added.

- Final adjustments and alignments are made.

Quality Control & Testing

Before a bogie is cleared for use, it undergoes rigorous quality control tests, including:

- Ultrasonic & X-ray testing: Checking for internal material defects.

- Dimensional inspection: Ensuring precise tolerances.

- Load testing: Simulating real-world loads.

- Vibration & fatigue tests: Testing durability over time.

Painting & Coating

To protect against corrosion and wear, bogies are coated with:

- Epoxy-based paints

- Zinc coatings for corrosion resistance

- Powder coatings for durability

Installation on Trains

After passing quality checks, bogies are transported to train manufacturing facilities where they are mounted onto train carriages using hydraulic lifts.

Variable Gauge Axle

The variable gauge axle is a crucial innovation in modern rail transport, allowing trains to adapt to different track widths. This system uses adjustable wheelsets that can change their gauge, or the distance between the wheels, making it possible to travel on both broad and narrow gauge tracks without changing the bogie.

This technology is particularly useful for international rail travel and is commonly used in regions where rail networks have varying track gauges. It enables trains to seamlessly cross borders or move between different track systems, improving efficiency and reducing downtime during transfers.

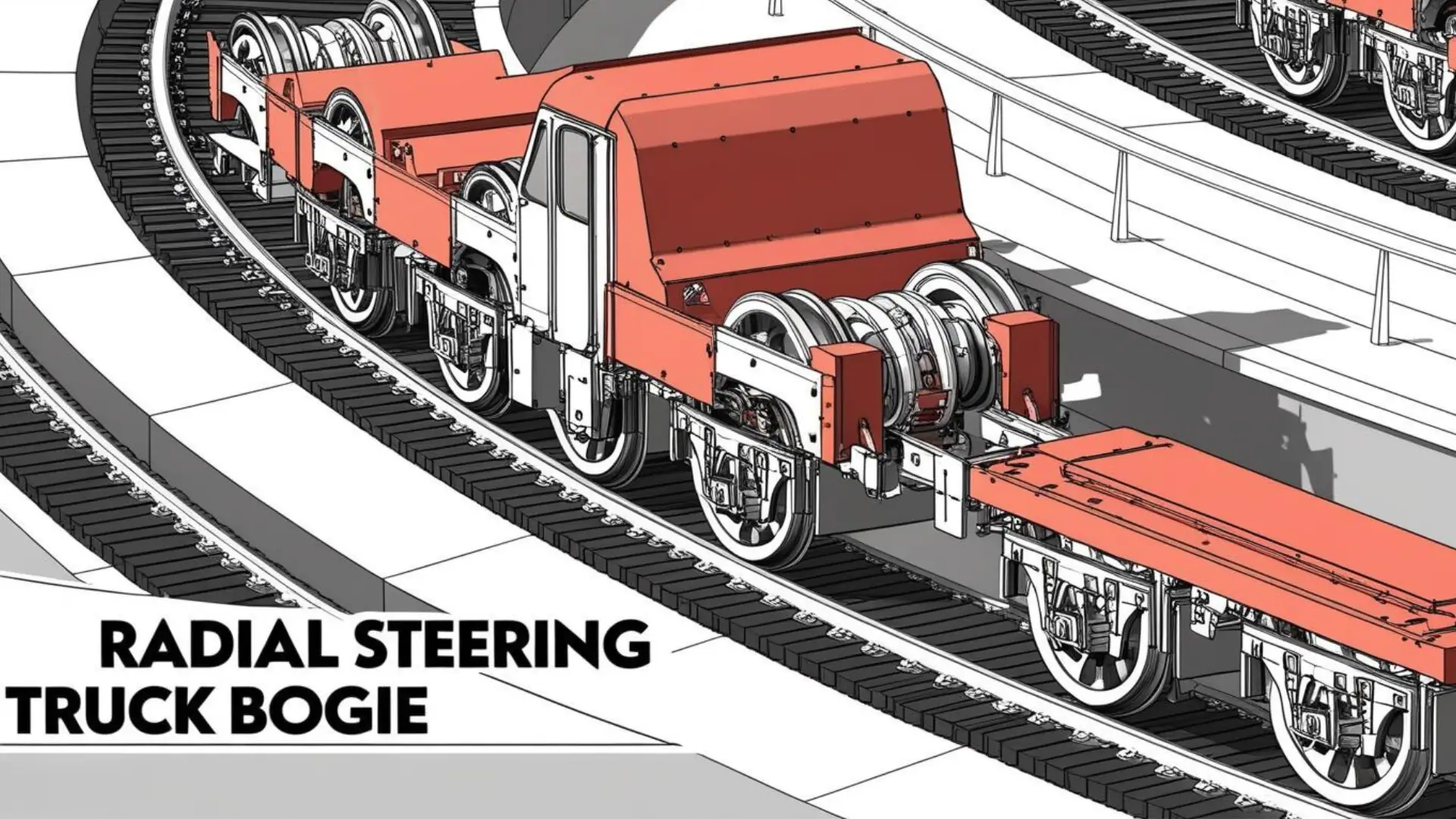

Radial Steering Truck Bogie

A radial steering truck bogie is designed to allow wheelsets to steer in the direction of the track curve. This innovation helps reduce wear on the rails and minimises the resistance that a train faces when negotiating tight curves.

The radial steering mechanism works by ensuring that the wheels are aligned with the direction of the curve, reducing friction and improving the train’s stability. This type of bogie is particularly useful for high-speed trains and those running on tracks with sharp curves.

Articulated Bogie

An articulated bogie connects two or more train cars, reducing the need for individual bogies under each car. This design helps distribute the weight more evenly across multiple axles and allows for better stability when navigating curves.

Articulated trains are more flexible and can have fewer bogies, which reduces weight and maintenance costs. This system is often used in high-speed trains, light rail, and some freight vehicles.

Tracked Vehicles

Tracked vehicles, often used in construction or mining, share similar bogie principles with railway vehicles. The key difference is that the “tracks” in these vehicles are typically continuous belts rather than rail tracks. These vehicles rely on bogies to ensure the weight is evenly distributed across the tracks and to improve mobility over uneven terrain.

How Do They Work?

Train bogies work by allowing the wheelsets to move and rotate independently within the bogie frame. This movement enables the vehicle to navigate curves, absorb shocks from the track, and minimise wear on the infrastructure. The bogie’s suspension system, typically consisting of springs or air suspension, absorbs vertical and lateral forces to ensure a smooth and stable ride.

The pivot mechanism within the bogie allows it to rotate relative to the vehicle frame, improving the vehicle’s ability to move along curves and uneven tracks. Additionally, modern bogies often include advanced systems for braking, traction, and noise reduction.

Role of Bogies

The role of bogies is central to the functionality and safety of railway vehicles. They are responsible for:

- Weight Distribution: Ensuring that the weight of the vehicle is evenly distributed across the wheelsets and that the track is not overburdened.

- Stability: Providing stability and reducing the risk of derailment by allowing the wheelsets to steer and pivot.

- Comfort: Absorbing shocks and vibrations to provide a smooth ride for passengers and protect the vehicle from damage.

- Efficiency: Minimising wear on both the train and the track, reducing maintenance costs and improving the overall efficiency of the rail system.

Bogie Types

There are several types of bogies, each designed for specific applications:

- Passenger Bogies: Designed for comfort and stability, these bogies often feature advanced suspension systems and noise reduction technologies.

- Freight Bogies: Built for strength and load-carrying capacity, these bogies focus on durability and stability.

- Powered Bogies: These bogies contain motors that drive the wheels directly or via a central power unit, used in diesel-electric and electric locomotives.

- Non-Powered Bogies: These are used in wagons or passenger cars that do not require independent propulsion.

Support

The bogie provides essential support for the vehicle’s weight and stability. The frame of the bogie holds the wheelsets and connects to the vehicle’s mainframe, providing the structural support required for safe and efficient travel.

Traction and Braking

Bogie systems often include power transmission components, such as gears and motors, to provide traction. These systems allow trains to accelerate and decelerate efficiently. In addition to traction, bogies include braking systems, such as disc or drum brakes, that are directly attached to the wheelsets to ensure effective stopping power.

Vibration Isolation

Vibration isolation in bogies is critical for reducing noise and improving passenger comfort. This is achieved through the suspension system, which uses air or spring-based components to absorb vibrations from the track.

Guidance

The guidance of a train is primarily controlled by the bogie, which keeps the wheelsets aligned with the track. This alignment is crucial for maintaining the vehicle’s direction and preventing derailment.

Suspension

The suspension system of a bogie ensures that the vehicle remains stable and absorbs shocks and vibrations from the track. This system typically consists of a combination of springs, air cushions, or hydraulic dampers that minimise the effects of track irregularities.

Power

Power within a bogie can be derived from the locomotive or an onboard power system. The power is transferred to the wheelsets via gears or belts, allowing the vehicle to move efficiently. Modern trains often use electric or diesel-electric power for optimal performance.

Final Notes

This train bogie overview is designed for engineers looking to understand the intricacies of bogie design, functionality, and their impact on train operations. By providing detailed information on bogie components, functionality, and various types, engineers can refer to this as a resource for designing, maintaining, and improving their own systems.

Get insights on industry news and posts.

Related Posts

October 29, 2025

A Class Tram | Details & History

Learn how the A Class Tram evolved from Z3, with A1 and A2 changes, braking,…

July 24, 2025

Tooling, Fixtures & Jigs Overview | Rail Applications

Tooling, jigs & fixtures is the physical interface between the design and the…

July 3, 2025

Melbourne Metro Tunnel Project | 2025 Update

Melbourne’s Metro Tunnel Project, set to open 2025 is the largest rail…