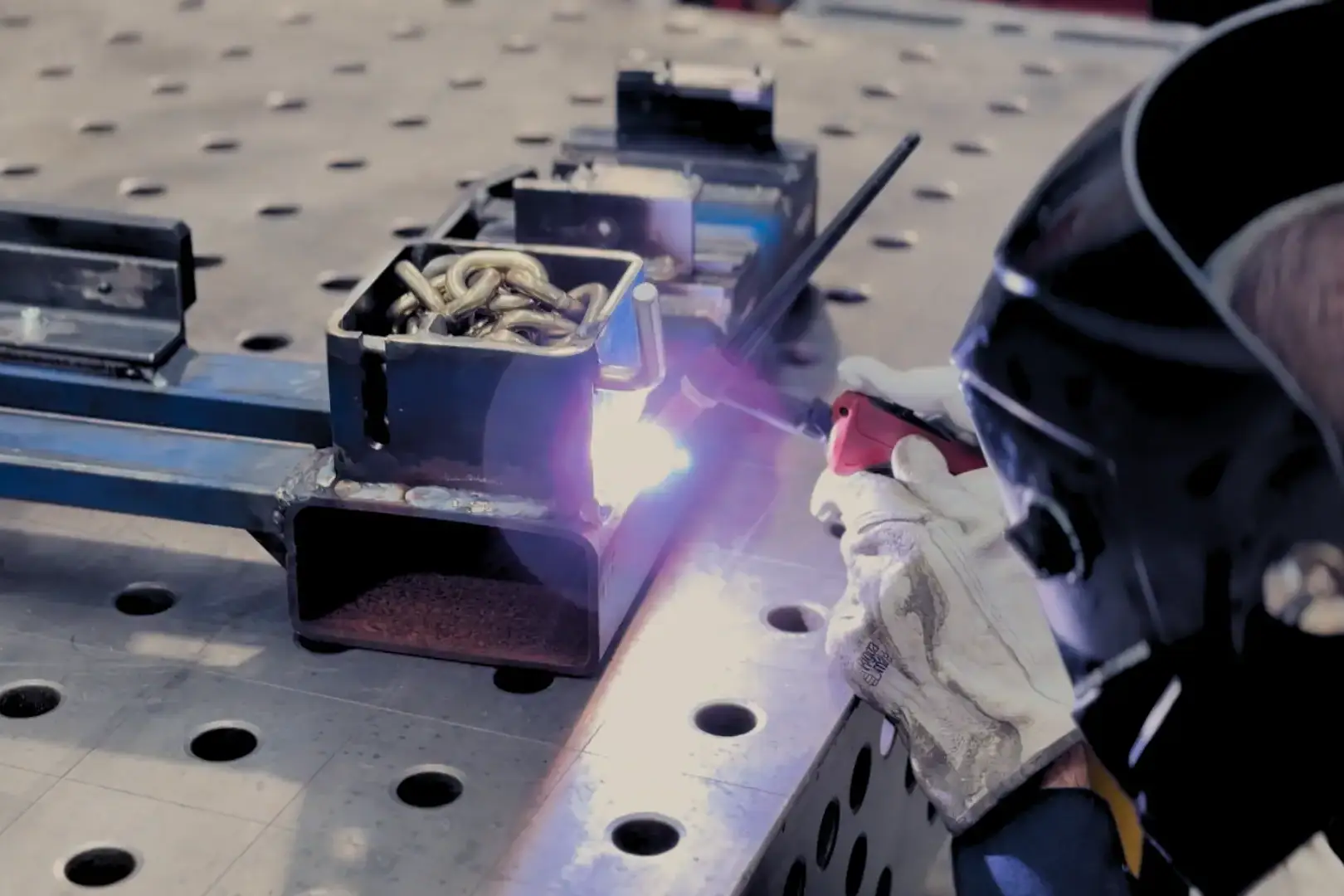

In the realm of manufacturing, TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a widely used technique renowned for its precision, versatility, and high-quality welds. From aerospace components to automotive parts, TIG welding plays a crucial role in delivering clean, reliable welds across various industries. This article delves into the mechanics of TIG welding, its applications, and why it is a preferred welding method in many manufacturing processes.

What is TIG Welding and How Does It Work?

TIG welding is a fusion welding process that uses a non-consumable tungsten electrode to create a weld joint. The weld area is protected from atmospheric contamination by an inert gas, typically argon or helium, which flows through the welding torch.

Unlike other welding methods, TIG welding does not require a flux or other consumable electrodes, which contributes to its cleaner welds. TIG welding produces clean, precise welds with minimal spatter, making it ideal for applications requiring exceptional weld quality.

The Role of Inert Gas in TIG Welding

Inert gases play a critical role in TIG welding by shielding the weld area from oxidation and other atmospheric contaminants. Argon, the most commonly used gas, provides a stable arc and smooth, clean welds.

Helium, though more expensive, can be used for increased penetration and higher welding speeds, particularly with thicker materials. Some welders also use a mixture of argon and helium to balance the advantages of both gases, achieving optimal results depending on the welding conditions.

The TIG Welding Process

During TIG welding, the welder controls the heat input and welding speed using a foot pedal or hand controls. The tungsten electrode, held in the welding torch, generates an arc with the workpiece, melting the base metal and forming the weld pool.

A separate filler metal may be added to the weld pool manually to reinforce the joint and achieve the desired weld profile. This manual addition of filler metal allows for precise control over the welding process, making TIG welding ideal for delicate and critical applications.

TIG Machine Controls

TIG welding machines feature various controls to adjust welding parameters such as current, voltage, and gas flow rate. These controls allow welders to tailor the welding process to suit specific materials, joint configurations, and welding positions, ensuring optimal weld quality and performance. Advanced TIG welding machines may include features like pulse welding, which alternates the current between high and low levels to control heat input more precisely. Pulse welding is particularly beneficial for thin materials, reducing the risk of warping or burn-through.

Key Steps in the TIG Welding Process

- Arc Initiation: The process begins with initiating the arc between the tungsten electrode and the workpiece. Some machines use high-frequency start or lift-arc start methods to strike the arc without contaminating the tungsten.

- Welding Heat Control: Using a foot pedal or fingertip control, the welder adjusts the current to control the heat input, allowing for precise control of the weld pool.

- Adding Filler Metal: If required, filler metal is manually added to the weld pool, controlling the amount and location of added material to achieve the desired weld profile.

- Shielding the Weld: Throughout the process, shielding gas flows around the weld area, protecting it from contamination and ensuring a clean, high-quality weld.

How Does a TIG Welder Work?

A TIG welder operates by creating an arc between the tungsten electrode and the workpiece. This arc generates intense heat, which melts the metal and forms the weld pool. The welder can precisely control the arc length, heat input, and filler metal application to achieve a high-quality weld. The non-consumable nature of the tungsten electrode means that the welder does not need to replace the electrode during the process, unlike consumable electrode processes like MIG welding.

Key Components of a TIG Welder

- Tungsten Electrode: The heart of the TIG welder, the tungsten electrode is non-consumable and responsible for maintaining a stable arc during welding. Tungsten’s high melting point allows it to withstand the heat generated during welding without degrading.

- Power Supply: The power supply provides the necessary current to create the arc between the tungsten electrode and the workpiece. TIG welders typically use either alternating current (AC) or direct current (DC), depending on the material being welded.

- Torch: The torch holds the tungsten electrode and delivers the shielding gas to the weld area. Torches are designed to be lightweight and easy to handle, providing the welder with precision control.

- Shielding Gas: Typically argon or helium, shielding gas protects the weld pool from atmospheric contamination, ensuring a clean and defect-free weld. Gas flow rates and selection are adjusted based on the type of material and welding position.

- Foot Pedal or Hand Control: These controls allow the welder to adjust the heat input in real-time, providing precise control over the welding process. By modulating the amperage, the welder can respond dynamically to the weld conditions.

Getting Started with TIG Welding

Starting with TIG welding requires an understanding of the equipment, techniques, and safety measures to ensure successful welds. Unlike other welding processes, TIG welding demands a high level of skill and coordination, making it essential to master the basics before tackling complex welds. If your looking for an easy way to get started Copamate offers comprehensive fabrication services to all industries.

Step-by-Step Guide to Getting Started with TIG Welding

- Select the Right Equipment: Choose a TIG welding machine that matches your specific needs, whether for light-duty or industrial applications. Consider factors like current range, duty cycle, and the types of materials you will be welding.

- Prepare the Work Area: Proper work area preparation is critical for successful TIG welding. Clean the work surface to remove contaminants such as rust, oil, or paint that could affect the weld quality. Use a wire brush or grinder to clean the metal, especially for materials like aluminium that form an oxide layer.

- Set Up the Machine: Adjust the welding machine settings according to the material type and thickness. Set the current, gas flow rate, and select the appropriate tungsten electrode type (e.g., thoriated for steel, ceriated for aluminium). Ensure all connections are secure and check the gas flow rate to match the welding conditions.

- Practice Torch Control: Mastering torch control is essential in TIG welding. Practice maintaining a consistent arc length and torch angle to ensure a steady weld bead. Spend time practicing on scrap metal to develop the muscle memory needed for consistent results.

- Start with Simple Joints: Begin with basic weld joints such as butt joints or lap joints to build your skills before moving on to more complex welds. Focus on maintaining a steady hand, controlling the heat input, and adjusting the filler metal as needed to achieve uniform weld beads.

TIG Welding Basics

TIG welding requires a steady hand and precise control of the welding torch. Welders must maintain the correct arc length, travel speed, and torch angle to achieve consistent and uniform welds. Proper joint preparation, including cleaning and fit-up, is essential to ensure successful TIG welding outcomes.

Key Techniques in TIG Welding

- Arc Length: Maintaining the correct arc length between the tungsten electrode and the workpiece is critical. Too close, and you risk contaminating the tungsten and causing weld defects; too far, and the arc becomes unstable, resulting in a weak weld.

- Travel Speed: Consistent travel speed ensures even heat distribution, crucial for weld penetration and bead appearance. An uneven travel speed can cause the weld bead to become inconsistent, leading to potential weak points in the weld.

- Torch Angle: Holding the torch at the correct angle (usually 15-20 degrees from the vertical) allows for better visibility of the weld pool and provides control over the molten metal. The angle should be adjusted based on the position and type of joint being welded.

- Filler Metal Application: Filler metal is added to the weld pool manually, and its application requires precise timing and placement. Too much filler can lead to excessive buildup, while too little can result in a weak weld.

TIG Welding Safety

Safety is paramount when performing TIG welding. The process involves high temperatures, intense light, and the use of gases, all of which pose potential hazards. Following proper safety protocols not only protects the welder but also ensures the quality and integrity of the welding process.

Key Safety Practices for TIG Welding

- Wear Protective Gear: Always wear appropriate personal protective equipment (PPE), including a welding helmet with a proper shade lens to protect your eyes from the intense arc light, gloves to protect your hands from heat and sparks, and flame-resistant clothing to prevent burns.

- Ensure Proper Ventilation: TIG welding produces fumes that can be harmful if inhaled. Work in a well-ventilated area or use exhaust systems to remove fumes. If working in confined spaces, consider using respirators to protect against harmful gases.

- Check Equipment Regularly: Inspect your welding equipment before each use to ensure that cables, connections, and gas lines are in good condition. Faulty equipment can not only compromise safety but also affect weld quality.

- Handle Gas Cylinders Safely: Shielding gas cylinders must be handled with care, stored upright, and secured to prevent tipping. Ensure that the regulator is properly fitted, and always turn off the gas supply when not in use.

- Avoid Electrical Shock: Ensure that the welding machine is properly grounded and avoid contact with live electrical components. Moisture can increase the risk of electric shock, so keep your work area dry.

TIG Welding Quality

The quality of a TIG weld is determined by factors such as bead appearance, penetration, and absence of defects like porosity, cracks, or undercuts. TIG welding is known for producing high-quality, aesthetically pleasing welds that require little to no post-weld cleaning. Proper technique, equipment settings, and joint preparation all contribute to the overall quality of the weld.

Factors Influencing TIG Welding Quality

- Welding Current: The welding current directly affects the penetration and heat input. Too much current can lead to burn-through, while too little can result in inadequate fusion.

- Gas Flow Rate: The flow rate of the shielding gas must be carefully controlled to protect the weld pool. A flow rate that is too high can cause turbulence, leading to contamination, while too low can result in insufficient shielding.

- Electrode Type and Size: The type and size of the tungsten electrode should be matched to the material and current level. Using the wrong electrode can lead to arc instability and poor weld quality.

- Material Cleanliness: Clean materials free of contaminants, oxides, or coatings are essential for quality TIG welding. Even small amounts of contamination can lead to weld defects, requiring rework and reducing overall weld strength.

Applications of TIG Welding

TIG welding is widely used across various industries, including aerospace, automotive, manufacturing, and art. Its precision and ability to weld thin materials make it ideal for applications requiring high-quality, aesthetically pleasing welds.

Key Industries and Uses of TIG Welding

- Aerospace: TIG welding is critical in aerospace applications where the quality and reliability of welds are of utmost importance. It is used to weld aluminium and titanium components, both of which are commonly found in aircraft structures.

- Automotive: In the automotive industry, TIG welding is used for exhaust systems, frames, and custom car parts. Its precision allows for clean welds on thin materials without the risk of burn-through.

- Manufacturing: TIG welding is prevalent in the manufacturing of precision equipment, where the weld quality directly impacts product performance. From food processing equipment to chemical storage tanks, TIG welding is essential in producing durable, corrosion-resistant welds.

- Art and Sculpture: Artists and sculptors often use TIG welding to create intricate metal sculptures. Its ability to weld without leaving excess spatter or slag makes it a preferred choice for metal art.

- Electronics: TIG welding’s precision is invaluable in the electronics industry for joining small components with minimal heat distortion. It is often used in the manufacture of battery packs, electrical enclosures, and sensor housings.

The Future of TIG Welding

Advancements in TIG welding technology continue to push the boundaries of what this process can achieve. Innovations such as automated TIG welding systems, advanced power sources, and improved electrode materials are enhancing the capabilities of TIG welding, making it more efficient and accessible.

Emerging Trends in TIG Welding

- Automation: The integration of robotic systems in TIG welding is revolutionising the industry by improving precision, repeatability, and speed. Automated TIG welding is especially beneficial in high-volume production environments where consistent weld quality is essential.

- Advanced Power Sources: Modern TIG welders are equipped with advanced power sources that offer features like variable frequency, waveform control, and pulse modulation, allowing for more precise control over the welding process.

- Hybrid Welding Techniques: Combining TIG welding with other welding methods, such as laser welding, is becoming more popular to take advantage of the strengths of each process. Hybrid welding can improve weld penetration, reduce heat input, and increase overall efficiency.

- Enhanced Electrode Materials: Ongoing research into new tungsten electrode materials and coatings is improving arc stability and extending electrode life. These advancements contribute to better weld quality and reduced downtime for electrode replacement.

- Portable TIG Welders: The development of portable, inverter-based TIG welders has made the process more accessible for on-site work and small workshops. These compact units offer high performance in a lightweight package, ideal for field repairs and mobile welding services.

Final Notes

TIG welding remains one of the most versatile and high-quality welding processes available today. From its precision and clean welds to its application across a wide range of industries, TIG welding continues to be a vital tool for manufacturers, artists, and engineers alike. Whether you’re new to welding or looking to refine your skills, understanding the intricacies of TIG welding can open the door to countless opportunities in metal fabrication.

Get insights on industry news and posts.

Related Posts

April 17, 2025

Types of Welding and What are They Used For?

Welding is a foundational process in modern manufacturing, fabrication and…

February 25, 2025

What is Fusion Welding | Types and Processes

Fusion welding, also known simply as metal welding, is a process where two or…

October 1, 2024

How to MIG Weld

MIG welding is one of the most versatile and user-friendly welding processes,…