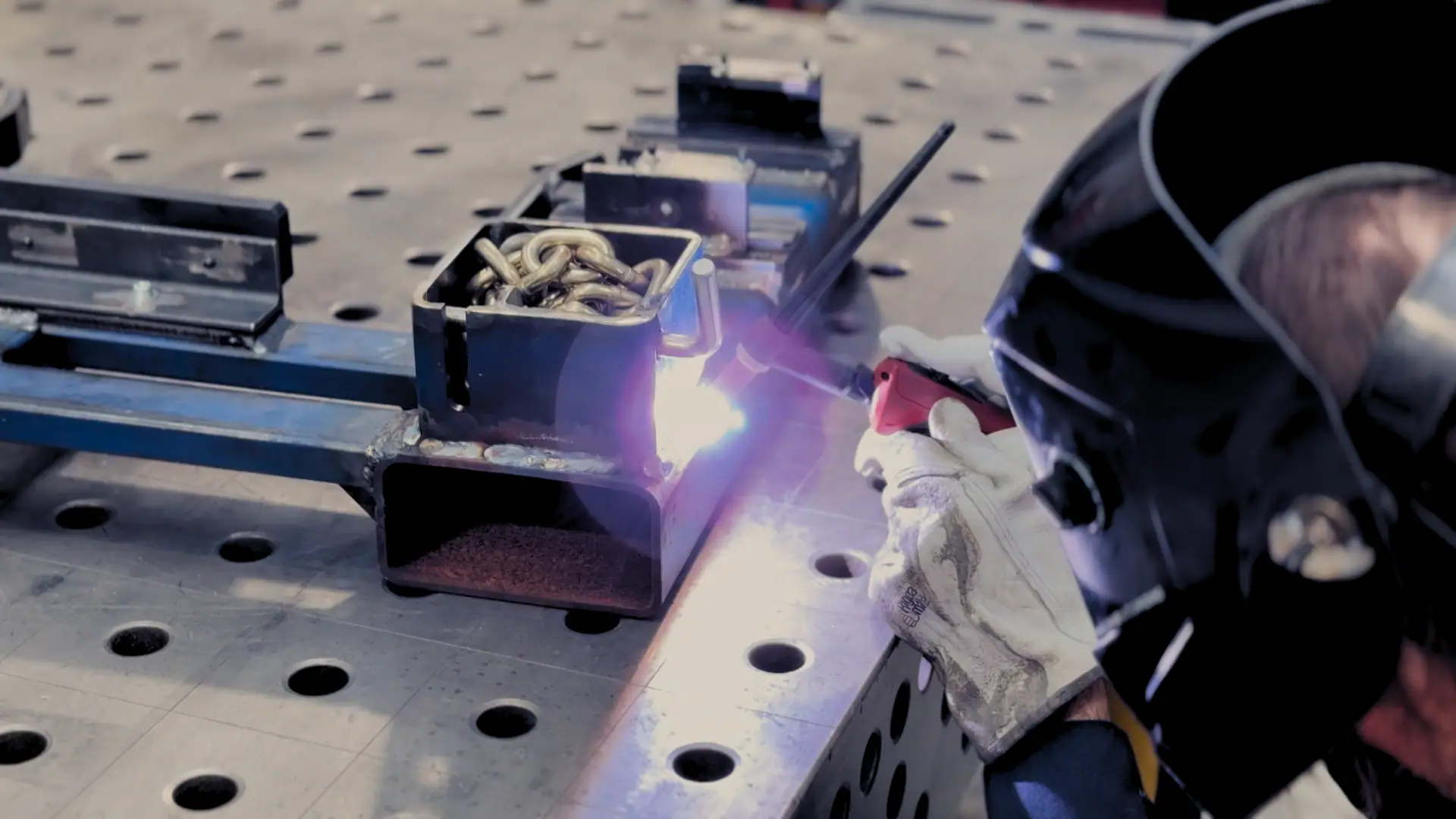

Fusion welding, also known simply as metal welding, is a process where two or more metal pieces are heated to extremely high temperatures until they melt and fuse together.

This process falls under homogeneous welding and can be performed with or without a filler material. Unlike other welding services that rely on pressure to create a joint, fusion welding depends solely on heat, making it distinct from processes like solid-state welding.

The fusion welding process is widely used in industries such as automotive, aerospace, construction, and manufacturing, providing strong and durable welds essential for structural integrity. Due to its versatility, fusion welding is a cornerstone of modern engineering, allowing manufacturers to produce high-quality, reliable structures that meet industry standards.

What is the Difference Between TIG and Fusion Welding?

TIG welding (Tungsten Inert Gas welding) is one of the most precise welding techniques used for high-quality welds. Fusion welding, on the other hand, is a broader category that includes various welding methods, including TIG welding. A specific technique known as Autogenous TIG Welding refers to a fusion welding process where two metal pieces are joined without the use of a filler rod.

TIG welding is widely used for materials requiring high precision and clean welds, such as stainless steel and aluminum. Due to its control and precision, TIG welding is often used in industries where weld quality is critical, such as aerospace and medical equipment manufacturing.

Fusion welding, in a broader sense, includes multiple processes beyond TIG, such as laser welding, plasma arc welding and electron beam welding, each offering different benefits depending on the application and material being welded.

Fusion Welding Processes

Fusion welding encompasses a variety of welding techniques, each suited for different applications and materials. The following are the main types of fusion welding:

1. Oxy-Fuel Welding (Oxyacetylene Welding)

Oxy-fuel welding is one of the oldest forms of welding, using a combination of oxygen and acetylene gas to produce a flame hot enough to melt metals. It is commonly used in metal fabrication, pipeline welding, and repair work. This method is particularly effective for welding thin materials and performing intricate work, as the flame can be precisely controlled.

2. Electric Arc Welding Processes

Electric arc welding uses an electric arc to generate heat, melting and fusing the base metals. The most common arc welding processes include:

- Metal Inert Gas (MIG) Welding (GMAW) – Uses a consumable wire electrode and shielding gas for fast and efficient welding. MIG welding is preferred in high-production environments due to its speed and ease of use.

- Tungsten Inert Gas (TIG) Welding (GTAW) – Uses a non-consumable tungsten electrode for precise and clean welds. This process is ideal for thin materials and applications requiring high-quality finishes.

- Plasma Arc Welding (PAW) – Uses a constricted arc and ionized gas for deep penetration welds, making it suitable for industrial and aerospace applications.

- Submerged Arc Welding (SAW) – Uses a continuously fed electrode and granular flux for high-quality welds with minimal spatter, making it ideal for thick metal sections.

- Flux Cored Arc Welding (FCAW) – Similar to MIG welding but with a flux-cored wire for additional shielding. This method is used for outdoor welding applications where wind might interfere with shielding gases.

3. Resistance Welding Processes

Resistance welding generates heat through electrical resistance to fuse metals. This method is commonly used in the automotive and sheet metal industries. The key types include:

- Resistance Spot Welding (RSW) – Used for joining overlapping sheets of metal with small weld nuggets. This method is widely used in car manufacturing.

- Resistance Seam Welding (RSEW) – Creates continuous weld seams using roller electrodes. It is commonly used for making watertight and airtight joints, such as in fuel tanks.

4. High-Energy Welding Processes

High-energy welding processes use concentrated energy sources to achieve deep penetration welds, making them ideal for aerospace and precision applications. The main types are:

- Electron Beam Welding (EBW) – Uses a focused beam of high-velocity electrons to generate heat and create deep welds. This process is conducted in a vacuum to prevent contamination.

- Laser Beam Welding (LBW) – Uses a high-powered laser to produce precise and strong welds with minimal distortion. It is often used for delicate electronic components and medical devices.

Advantages of Fusion Welding

Fusion welding offers numerous benefits, making it a preferred choice in various industries:

- Strong and durable joints – The welded materials fuse at a molecular level, creating robust bonds that withstand stress and fatigue.

- High precision – Techniques like TIG and laser welding provide clean, precise welds with minimal distortion, making them ideal for applications requiring aesthetic quality and strength.

- Versatile applications – Fusion welding can be used for different metals, including steel, aluminum, titanium, and exotic materials like nickel alloys.

- Automation-friendly – Many fusion welding processes can be automated for high efficiency, consistency, and reduced labor costs.

- Ability to join complex geometries – Advanced methods such as electron beam welding allow for deep penetration and precise control, making them suitable for intricate assemblies.

Challenges and Considerations

Despite its advantages, fusion welding also has some challenges:

- High heat input – Can cause distortion in thin materials, requiring additional post-processing steps to correct warping.

- Equipment cost – Some processes, such as laser and electron beam welding, require expensive equipment and specialised facilities.

- Skill requirement – Techniques like TIG welding require significant training and expertise to achieve high-quality welds.

- Safety concerns – Some welding methods involve intense radiation, high temperatures, and toxic fumes, requiring protective gear and proper ventilation.

- Material compatibility – Not all metals are easily welded using fusion welding, and some require specialised processes or pre-weld treatments.

Applications of Fusion Welding

Fusion welding is utilised in various industries, including:

- Aerospace – Used for assembling aircraft structures, engines, and spacecraft components.

- Automotive – Applied in manufacturing vehicle frames, exhaust systems, and structural reinforcements.

- Shipbuilding – Essential for welding large steel structures in marine construction.

- Medical device manufacturing – Used for precision welding of surgical instruments and implants.

- Construction and infrastructure – Applied in welding structural beams, pipelines, and bridges.

Final Notes

Fusion welding plays a crucial role in modern manufacturing and engineering, offering strong, high-quality welds suitable for a wide range of applications. Understanding the different fusion welding processes, their advantages, and challenges helps businesses select the right method for their needs.

Whether it’s MIG welding for fast production or laser welding for precision, fusion welding remains a fundamental technique in metal fabrication. As technology advances, fusion welding techniques continue to evolve, enabling manufacturers to produce stronger, more reliable, and efficient welds across various industries.

Get insights on industry news and posts.

Related Posts

April 17, 2025

Types of Welding and What are They Used For?

Welding is a foundational process in modern manufacturing, fabrication and…

October 1, 2024

How to MIG Weld

MIG welding is one of the most versatile and user-friendly welding processes,…

September 24, 2024

What is TIG Welding? | Comprehensive Overview

TIG welding is a fusion welding process that uses a non-consumable tungsten…