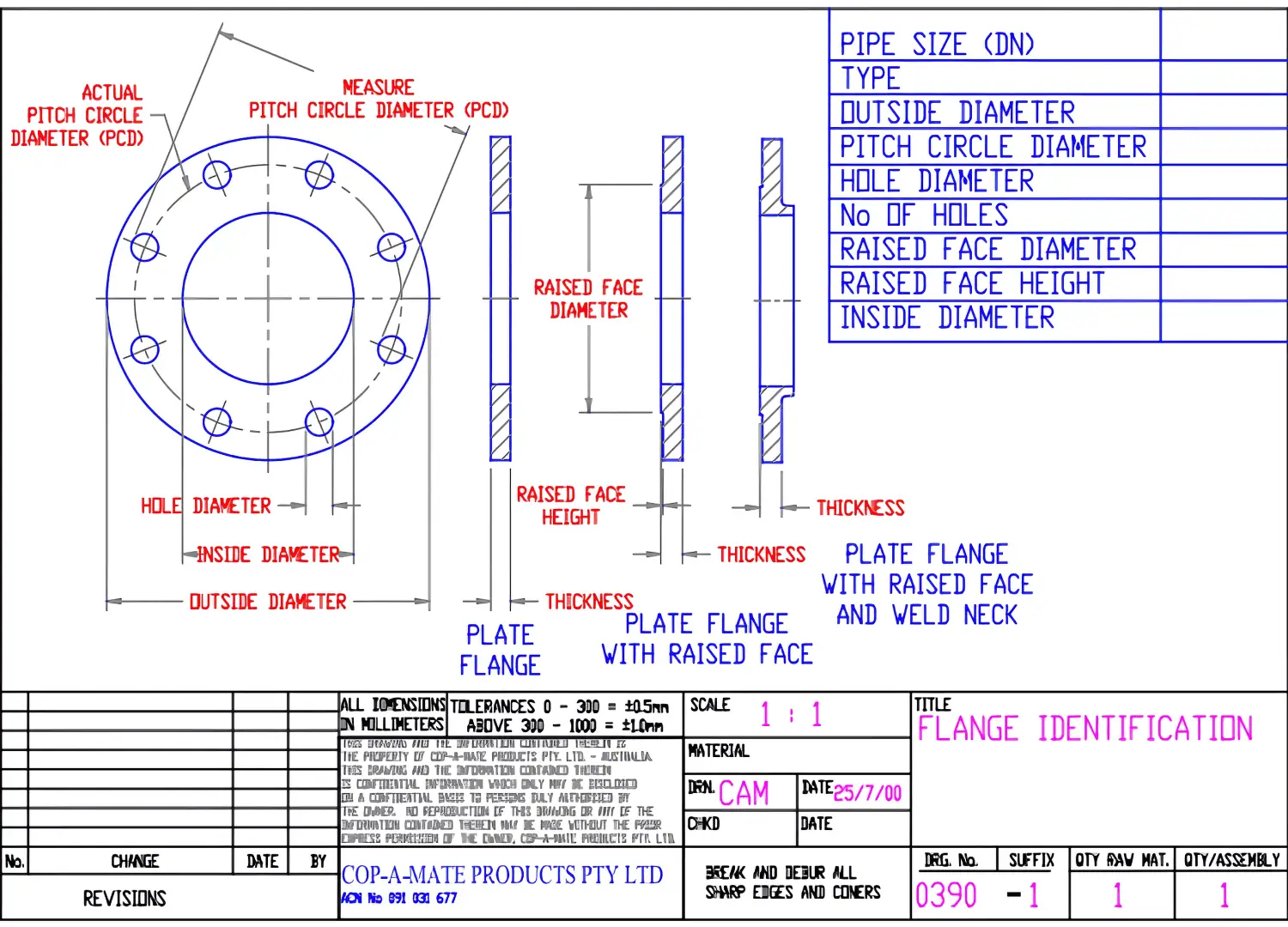

Copamate Flange Adaptor

The Copamate Flange Adaptor creates a quick and easy way to connect pipes without the hassle of fabrication.

Features

- Safe working pressure and testing pressure up to 50c

- Certified to AS1432 – 1996

- Electrolysis Protection – Our product has a superior coating system designed for electrolysis protection.

- Copmate sockets designed and manufactured in accordance with AS3688.

- Simple installation

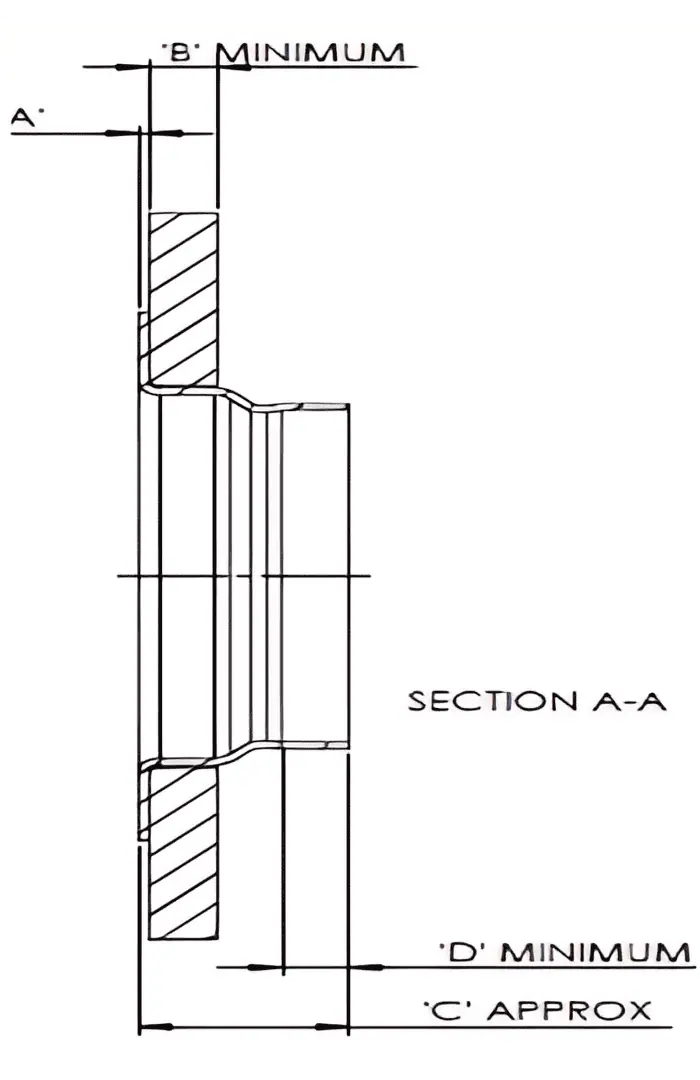

| A’ | B’ | C’ | D’ | ||||

|---|---|---|---|---|---|---|---|

| Size | Table D | ABLE E | DIN 16 | ANSI 150 | APPROX | MINIMUM | |

| 20 | 1.6 | 10 | 10 | 16 | 11 | 23 | 7.5 |

| 25 | 1.6 | 10 | 10 | 16 | 14.5 | 23 | 7.5 |

| 32 | 2 | 10 | 10 | 18 | 16 | 23 | 7.5 |

| 40 | 2 | 12 | 12 | 18 | 17.5 | 26 | 7.5 |

| 50 | 2 | 12 | 12 | 20 | 19 | 28 | 7.5 |

| 65 | 2 | 12 | 12 | 20 | 22.5 | 30 | 7.5 |

| 80 | 2 | 12 | 12 | 20 | 24 | 36 | 11.1 |

| 100 | 2 | 12 | 13 | 22 | 24 | 39 | 11.1 |

| 125 | 2 | 14 | 14 | 22 | 24 | 43 | 11.1 |

| 150 | 2.5 | 14 | 17 | 24 | 25.5 | 46 | 14.2 |

| 200 | 2.5 | 14 | 19 | 26 | 28.5 | 51 | 14.2 |

| 250 | 3 | 16 | 22 | 29 | 30.5 | 57 | 18 |

| 300 | 3 | 19 | 25 | 32 | 32 | 60 | 18 |

| 350 | 4 | 22 | 29 | 35 | 35 | 60 | 20 |

| 400 | 4 | 22 | 32 | 38 | 37 | 60 | 20 |

| 450 | 5 | 25 | 35 | 42 | 40 | 60 | 20 |

Copper Tube

Safe working pressure and testing pressure up to 50c – AS1432 – 1996

| DN (mm) | Imperial (Inches) | Type A | Type B | Socket | ||

|---|---|---|---|---|---|---|

| Psw | Pt | Psw | Pt | |||

| 6 | 1/8″ | 11990 | 17980 | 8710 | 13070 | |

| 8 | 1/4″ | 9320 | 13970 | 6820 | 10240 | |

| 10 | 3/8″ | 8670 | 13300 | 7630 | 11440 | |

| 15 | ½” | 6330 | 9490 | 5590 | 8380 | |

| 20 | ¾” | 5860 | 8790 | 4110 | 6170 | |

| 25 | 1″ | 5840 | 7560 | 3680 | 5520 | 3500 |

| 32 | 1 ¼” | 4370 | 4940 | 3620 | 4370 | 2750 |

| 40 | 1 ½” | 3290 | 4940 | 2430 | 3620 | 2500 |

| 50 | 2” | 2440 | 3670 | 1840 | 2900 | 1750 |

| 65 | 2 ½” | 1650 | 2610 | 1430 | 2250 | 1600 |

| 80 | 3” | 2020 | 3030 | 1610 | 2420 | 1600 |

| 100 | 4” | 1460 | 2190 | 1160 | 1740 | 1600 |

| 125 | 5” | 1160 | 1740 | 960 | 1440 | 1400 |

| 150 | 6” | 910 | 1370 | 720 | 1090 | 1400 |

| 200 | 8” | 1050 | ||||

| 250 | 10” | 1050 | ||||

| 300 | 12” | 1050 | ||||

| 350 | 700 | |||||

| 400 | 700 | |||||

| 450 | 700 | |||||

Installation Instructions

- Unpack with care

- Avoid impact & direct flame to backing flange.

- Avoid stress – cut tube, away from brazed joint before brazing – rear of backing flange away from socket.

- Braze using normal brazing practices – ensure socket is square.

- Allow socket to cool before sliding flange up to it. Insert gasket – if required.

- Hand tighten bolts using normal bolting practice to tighten backing flange.

- If coating is damaged repair with Alkyd Enamel.

Electrolysis Protection

Electrolysis occurs over time when two dissimilar metals are in contact. Our product has a superior coating system designed for electrolysis protection. No gasket is required between the mild steel flange and copper socket. Our product has greater longevity and time proven quality with inbuilt UV resistance keeping the product like new.