Full scale manufacturing based in Melbourne.

ISO 9001 manufacturing

Copamate has been involved in the manufacturing Melbourne industry for more than 30 years, satisfying clients with timely results underscored by our ISO 9001 and IRIS standards. Our team is capable of producing difficult to source items with an attention for detail.

We are capable of manufacturing small to large products taking you through the engineering and design process, all the way to assembly if needed. Our goal is to provide you with your desired outcome and specifications.

Capabilities

| Engineering | High Precision Machining Centre | Sheet Metal Fabrication | Painting & Coating | Maintenance & Refurbishment | Other |

| Design Support | CNC Lathe | Clinching Machine | Coating & Wet Paint | Fibreglass New/Repairs | Kiln – 1200 Degrees Celsius |

| Drafting/Engineering | CNC Milling | CNC Laser | Protective Coatings | Jigs & Fixtures | Testing |

| Reverse Engineering | Digital Cold Spray | CNC Press Brake | On-Site Painting & Coatings | General Maintenance | Heat Treatment |

| Seismic Calculations | Additive Manufacturing | Stamping Machines – 45,50,300 & 400 tonne | Heat Paint | Testing | Stock Holding |

| Bespoke Solutions | Turret Punching | Welding – Spot, Mig, Tig | Hot-Dip Galvanising | Logistics | |

| Technical Support | Vertex Quality Measuring | Sheet Rolling | Assembly | ||

| NDT Test | Profile Rolling | ||||

| Turret Punching | |||||

| Pipe Bending |

Our Standards

ISO 9001

ISO 2768:1

ISO 1554.1

AS/NZS 1554.6

APAS 0502

AS 1665

ISO 22163:2023 (IRIS)

ISO 9606

ISO 13920:C

EN15085 (soon)

AUKUS

DISP(waiting for approval)

AS 3992

AS 4041

AS 1210

AS/NZS 1554.1

AS4100

AS4037

AS9100

AS 4458

AS 3992

AS/NZS 1554.6

AS/NZS 1665

ISO 14001 (soon)

Need manufacturing solutions?

Contact us for your free production facility visit.

Engineering & Design

Engineering & design before production

Depending on the stage of your manufacturing process, we offer engineering and design services to transform your product concept into a detailed drawing ready for production.

We have delivered custom engineering and design solutions for rail, infrastructure and automotive. Copamate has built its reputation on engineering products such as valves and pipeline products, consistently delivering on product engineering and design.

Windows

Wear Plates

Equalizer Beams

Manufacturing Production in Melbourne

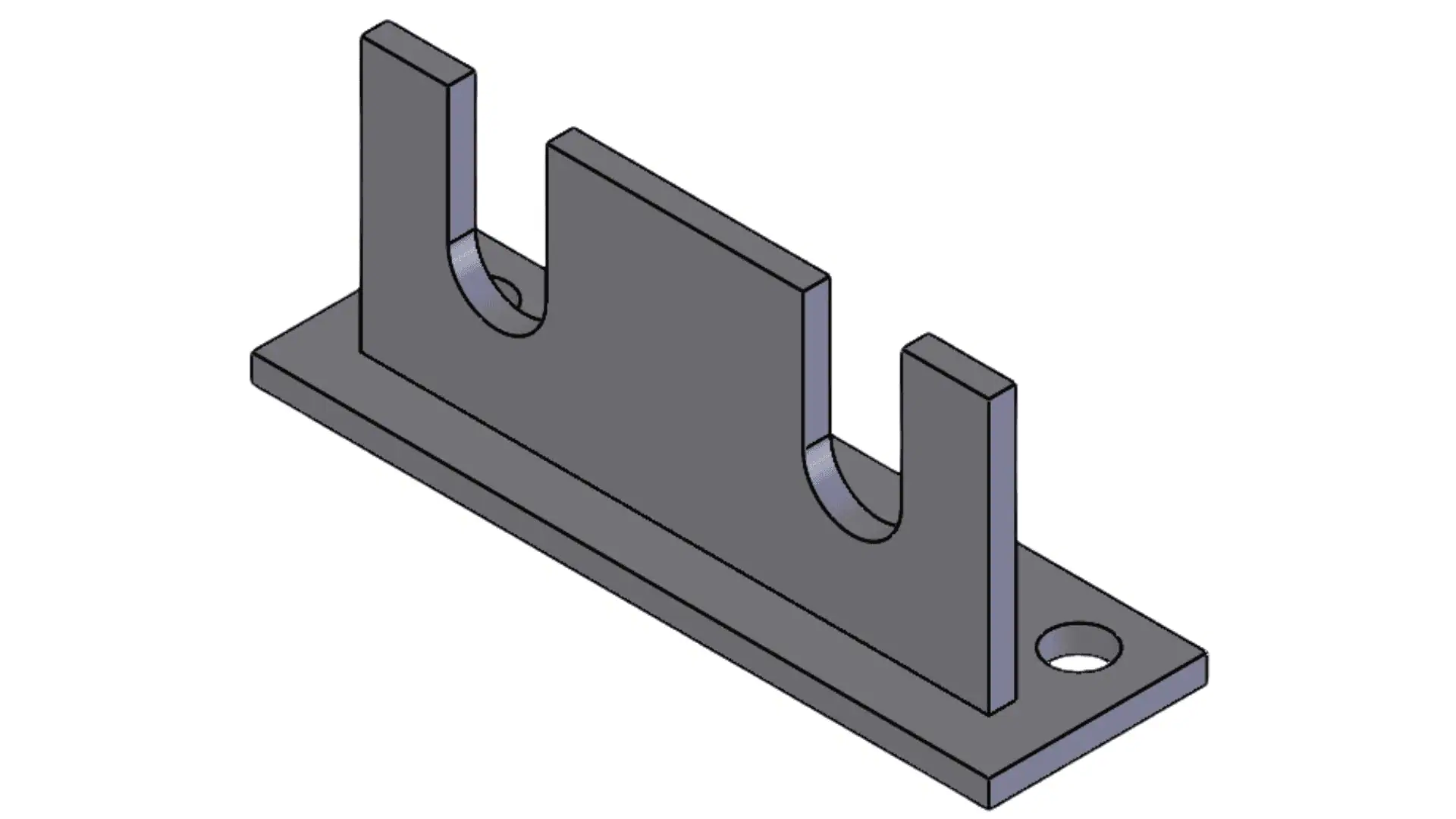

Product fabrication

At Copamate, we pride ourselves on our all-encompassing in-house Australian manufacturing capabilities. Whether it’s welding, precision machining, laser cutting or painting, we have the tools and expertise to handle it. Our production facility stands out for its diversity and comprehensive solutions, ensuring every project is completed to your specifications.

With a reputation for delivering across Australia, Copamate consistently adheres to project timelines while upholding industry standards. Our involvement in the world’s largest tram refurbishment program is a testament to our commitment to reliability.

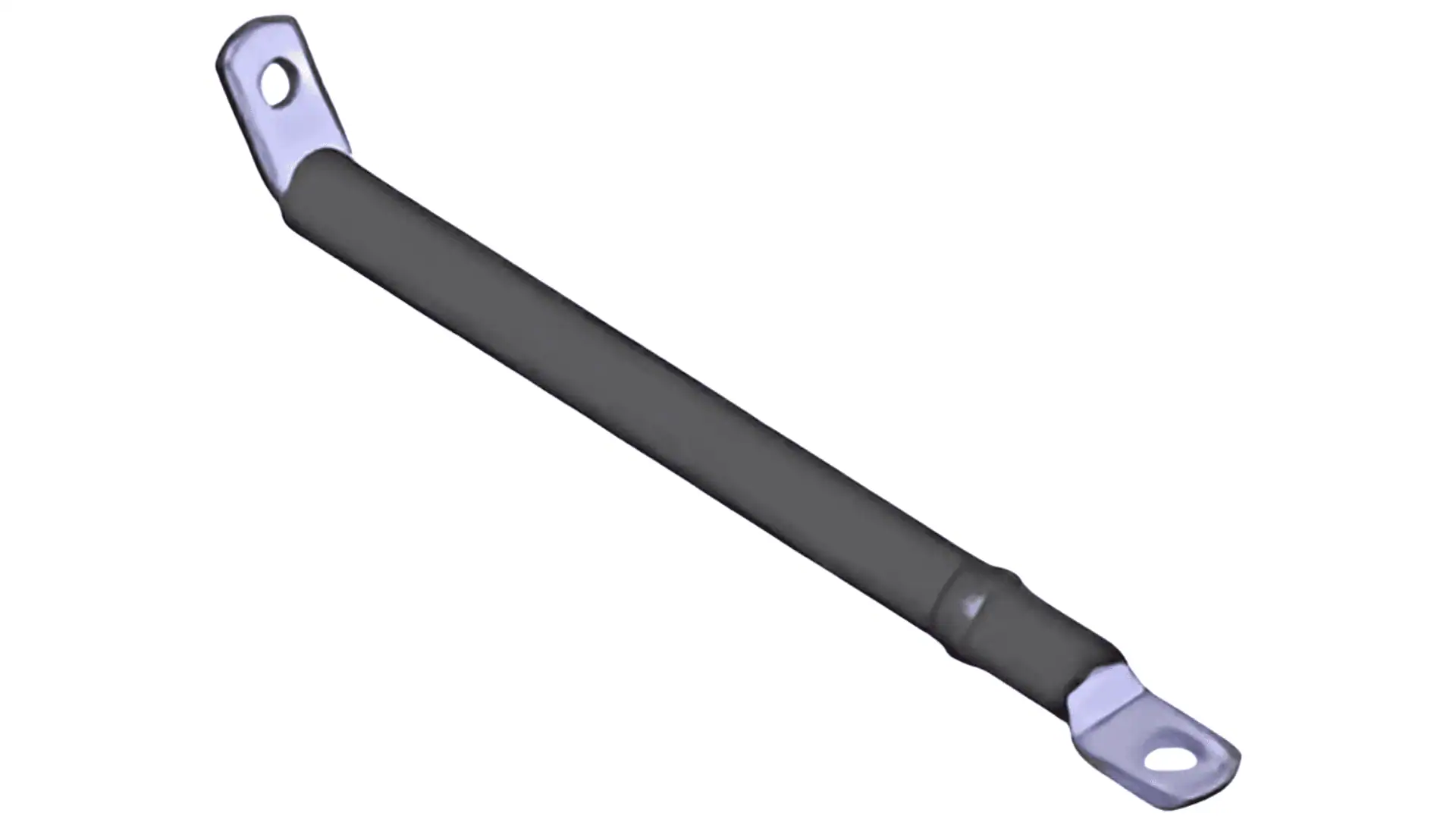

Sand Pipes

Shunt Assemblies

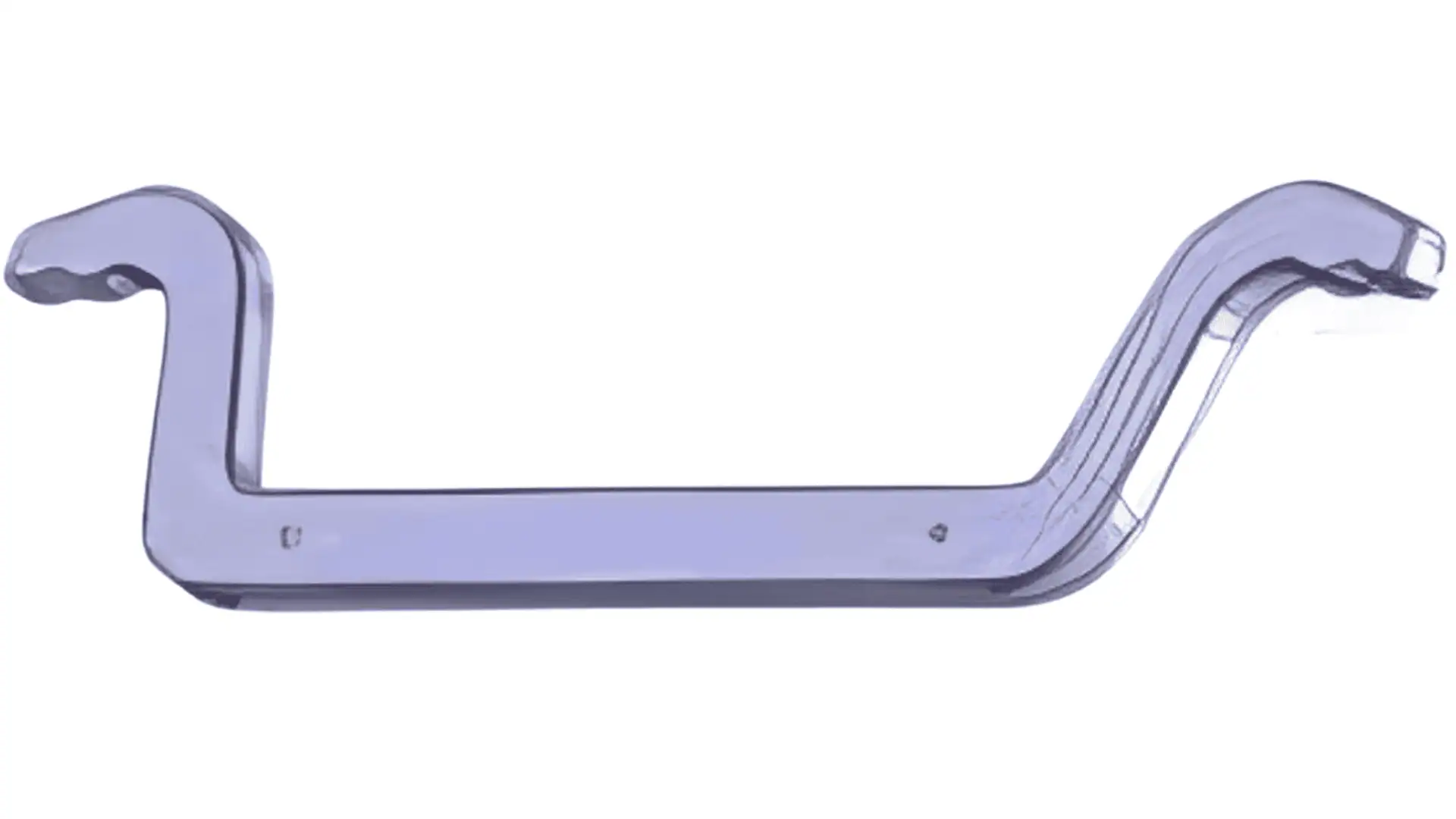

Brake Hose Support

Product Assembly

Finalising your project

Once production has taken place our team is capable of product assembly for your project. No matter the size we are qualified to assemble with precision. Our quality inspectors review all products before leaving the facility, we sure our standards have been applied to all Copamate projects.

Contact us, we will analyse your project and let you know if we can help free of charge.

Bespoke manufacturing in Melbourne.

Contact us for your project solutions.